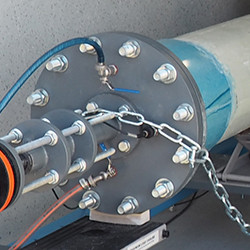

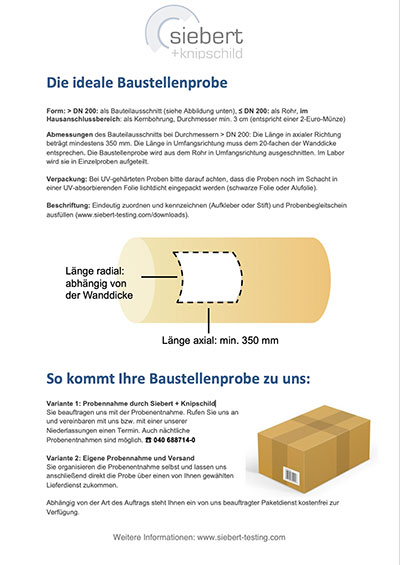

Standard material testing about the technical characteristic values are set in CIPP and other sewer renovation techniques. As an independent, accredited testing laboratory we document your remediation project success and certify if the construction site samples comply the requirements regarding to the mechanical characteristic values. Next to the bending strength, it affects the determination of the wall thickness and the modulus of elasticity (E-Modul).

You create values for generations. We deliver the proof.

All testings are according to the procurement and comply with the requirements of the current sets of rules (DWA-A 143-3, DIBt-admission).

All testings are used for controlling so that the delivered quality is equal to the ordered quality. Any questions about the requirements, provisions, or sampling? We are happy to answer you.

• fracture mechanical test

• gas chromatography

• DSC-Analysis

• 3D-Microscopy

• Dynamic-Mechanical Analysis

• ultrasound testing

• IR-Spectroscopy

Contact

Andreas Haacker is Siebert + Knipschild’s director. He is a chemical engineer with a diploma and an expert in the areas of plastic quality assurance in the drainage area for more than 15 years. His concerns in consultation of costumer are the useful and the successful application and further development of CIPP audit procedures as well as related remediation techniques.

Haacker is a committee member of the DIN and the DIBt as well as on European level (ZEN) and, since 2017, president of the pipeline renovation association (RSV).

Any questions? You can contact us by phone at 040 688714-0 or by e-mail

Testing of CIPP (main sewer)

Pos. 1.1.1

Testing the short time bending stress, determination of the short time E-modul and the wall thickness in the 3-point-bend test according to DIN EN ISO 178 (in combination with DIN EN ISO 11296-4), 5 individual testing per sample according to paragraph 7.2.2 der DWA-A 143-3 regular testing

Pos. 1.1.2

Testing the waterthightness of the Laminate in dependence to DIN EN 1610 with 0,5 bar vacuum, testing time of 30 min according to paragraph 7.2.9 of the DWA-A 143-3 regular testing

Pos. 1.1.3

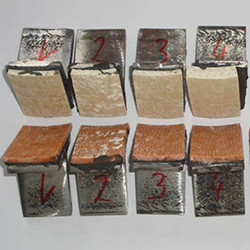

Testing the chemical suitability of fibres, proof for the use of E-CR-Glas, the resin and the chemical suitability of the used aggregates according to DIN EN ISO 175. Storage for 24h at 50 °C. Testing medium: sulphuric acid (H2S04) – 10% water solution requirements position

Pos. 1.1.4

As before, testing medium: caustic soda(NaOH) – 3% water solution requirements position

Pos. 1.1.5

Determination of glas relation and pitch relation through calcination methods (ash content dertermination) according to DIN EN ISO 1172 paragraph 7.2.8 of the DWA-A 143-3 requirements position

Pos. 1.1.6

Determination of the 24h-E-Moduls, determination of the creep tendency according to DIN EN ISO 899-2 in conjunction with the short-term value (DIN EN ISO 178 / DIN EN ISO 11296-4) according to paragraph 7.2.4 of the DWA-A 143-3 needs-related examination for repetition

Pos. 1.1.7

Testing of the residual styrene content in laminate samples for pipes in water protection areas according to DIN 53394-2 paragraph 7.2.5 of the DWA-A 143-3 needs-related examination for repetition

Pos. 1.1.8

Testing of the accordance of the used reactive resins through FT-IR-spektral analysis according to ASTM D5576 paragraph 7.2.7 of the DWA-A 143-3 needs-related examination for repetition